| 45°铣刀 | 45°milling cutter |

|

|

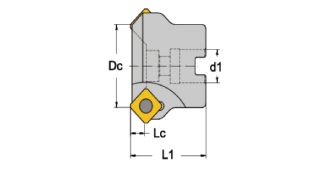

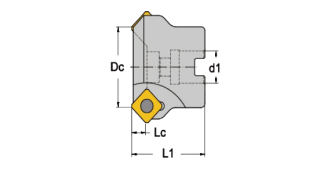

| Type |

Dc mm |

d1 mm |

L1 mm |

Lcmm | Z | Insert Type | Screw | Key |

| M45.SE12.B22.040.Z03 | 40 | 22 | 40 | 6.5 | 3 | SE..12T3.. | SR14-601 | TORX15 |

| M45.SE12.B22.050.Z04 | 50 | 22 | 40 | 6.5 | 4 | |||

| M45.SE12.B22.063.Z05 | 63 | 22 | 40 | 6.5 | 5 | |||

| M45.SE12.B27.080.Z06 | 80 | 27 | 50 | 6.5 | 6 | |||

| M45.SE12.B32.080.Z06 | 100 | 32 | 50 | 6.5 | 6 | |||

| M45.SE12.B40.125.Z07 | 125 | 40 | 63 | 6.5 | 7 | |||

| M45.SE12.B40.160.Z07 | 160 | 40 | 63 | 6.5 | 7 | |||

| M45.SE12.B60.200.Z10 | 200 | 60 | 63 | 6.5 | 10 | |||

| M45.SE12.B60.250.Z13 | 250 | 60 | 63 | 6.5 | 13 |

|

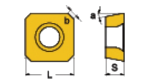

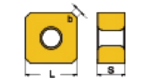

Insert Type |

D mm |

a° |

S mm |

b mm |

| SE..12T3.. | 12.7 | 20 | 3.8 | 2.2 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| SEMT12T3AFIN-76 | FPK20 | - | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 40-250 | 0.25 | 0.20 | 0.20 | 0.15 | - | 0.30 | 0.25 | 0.25 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

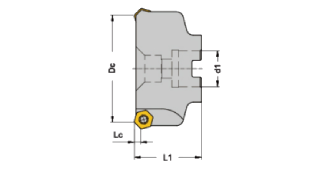

| 45°铣刀 | 45°milling cutter | |

|

|

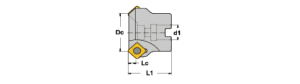

FIG1 |

|

FIG2 | |

| Type |

Dc mm |

d1 mm |

L1 mm |

L2 mm |

Lcmm | Z | Insert Type | Screw | Key |

Drawing No. |

| M45.SP12.W25.025.Z02 | 25 | 25 | 38 | 95 | 7 | 2 | SP..1204.. | FCS1030 | TORX20 | FIG1 |

| M45.SP12.W32.032.Z03 | 32 | 32 | 44 | 105 | 7 | 3 | ||||

| M45.SP12.W32.040.Z04 | 40 | 32 | 44 | 105 | 7 | 4 | ||||

| M45.SD09.B22.040.Z04 | 40 | 22 | 40 | / | 5 | 4 | SD..09T3.. | FCS359 | TORX15 | FIG2 |

| M45.SD09.B22.040.Z06 | 40 | 22 | 40 | / | 5 | 6 | ||||

| M45.SD09.B22.050.Z04 | 50 | 22 | 40 | / | 5 | 4 | ||||

| M45.SD09.B22.050.Z08 | 50 | 22 | 40 | / | 5 | 8 | ||||

| M45.SD09.B22.063.Z05 | 63 | 22 | 40 | / | 5 | 5 | ||||

| M45.SD09.B22.063.Z10 | 63 | 22 | 40 | / | 5 | 10 | ||||

| M45.SD09.B22.080.Z06 | 80 | 22 | 50 | / | 5 | 6 | ||||

| M45.SD09.B27.080.Z12 | 80 | 27 | 50 | / | 5 | 12 | ||||

| M45.SD09.B27.100.Z07 | 100 | 27 | 50 | / | 5 | 7 | ||||

| M45.SD09.B32.100.Z14 | 100 | 32 | 50 | / | 5 | 14 | ||||

| M45.SP12.B16.040.Z03 | 40 | 16 | 40 | / | 7 | 3 | SP..1204.. | FCS1030 | TORX20 | |

| M45.SP12.B22.050.Z04 | 50 | 22 | 40 | / | 7 | 4 | ||||

| M45.SP12.B22.063.Z05 | 63 | 22 | 40 | / | 7 | 5 | ||||

| M45.SP12.B27.080.Z06 | 80 | 27 | 40 | / | 7 | 6 | ||||

| M45.SP12.B32.100.Z07 | 100 | 32 | 50 | / | 7 | 7 | ||||

| M45.SP12.B40.125.Z08 | 125 | 40 | 63 | / | 7 | 8 | ||||

| M45.SP12.B40.160.Z09 | 160 | 40 | 63 | / | 7 | 9 | ||||

| M45.SX15.B22.063.Z05 | 63 | 22 | 40 | / | 7 | 5 | SX..1505.. | FCS378 | TORX15 | |

| M45.SX15.B27.080.Z06 | 80 | 27 | 50 | / | 7 | 6 | ||||

| M45.SX15.B32.100.Z07 | 100 | 32 | 50 | / | 7 | 7 | ||||

| M45.SX15.B40.125.Z08 | 125 | 40 | 63 | / | 7 | 8 | ||||

| M45.SX15.B40.160.Z09 | 160 | 40 | 63 | / | 7 | 9 |

|

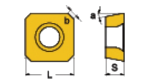

Insert Type |

D mm |

a° |

S mm |

b mm |

| SD..09T3.. | 9.52 | 15 | 3.97 | 1.2 | |

| SP..1204.. | 12.7 | 11 | 4.76 | 1.4 | |

| SX..1505.. | 14.7 | 14 | 5.56 | 3 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| SDMT09T3AEN-D57 | FPK20 | FCM20 | FPK20 | - |

| SPMT1204AEN | FPK20 | - | FPK20 | - |

| SXKR1505AEN | FCP20 | - | FCK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 25-160 | 0.25 | 0.20 | 0.20 | 0.15 | 0.12 | 0.30 | 0.25 | 0.25 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 45°铣刀-负型 | 45°milling cutter - negative type |

|

|

| Type |

Dc mm |

d1 mm |

L1 mm |

Lcmm | Z | Insert Type | Screw | Key |

| M45.SN12.B22.050.Z04 | 50 | 22 | 40 | 6.5 | 4 | SN.X1205.. | FS1459 | TORX15 IP |

| M45.SN12.B22.050.Z06 | 50 | 22 | 40 | 6.5 | 6 | |||

| M45.SN12.B22.063.Z06 | 63 | 22 | 40 | 6.5 | 6 | |||

| M45.SN12.B22.063.Z08 | 63 | 22 | 40 | 6.5 | 8 | |||

| M45.SN12.B27.080.Z07 | 80 | 27 | 50 | 6.5 | 7 | |||

| M45.SN12.B27.080.Z10 | 80 | 27 | 50 | 6.5 | 10 | |||

| M45.SN12.B32.100.Z08 | 100 | 32 | 50 | 6.5 | 8 | |||

| M45.SN12.B32.100.Z12 | 100 | 32 | 50 | 6.5 | 12 | |||

| M45.SN12.B40.125.Z10 | 125 | 40 | 63 | 6.5 | 10 | |||

| M45.SN12.B40.125.Z16 | 125 | 40 | 63 | 6.5 | 16 | |||

| M45.SN12.B40.160.Z12 | 160 | 40 | 63 | 6.5 | 12 | |||

| M45.SN12.B40.160.Z20 | 160 | 40 | 63 | 6.5 | 20 |

|

Insert Type |

L mm |

S mm |

b mm |

| SN.X1205.. | 12.7 | 6.33 | 1.5 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| SNMX120512-F57 | FPK20 | FCM20 | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 25-160 | 0.25 | 0.20 | 0.20 | 0.15 | 0.12 | 0.30 | 0.25 | 0.25 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 45°铣刀-负型 | 45°milling cutter - negative type |

|

|

| Type |

Dc mm |

d1 mm |

L1 mm |

Lcmm | Z | Insert Type | Screw | Key |

| M45.HN07.B22.050.Z05 | 50 | 22 | 40 | 3.5 | 5 | HN..0704.. | 12146034500 | TORX15 |

| M45.HN07.B22.063.Z06 | 63 | 22 | 40 | 3.5 | 6 | |||

| M45.HN07.B27.080.Z08 | 80 | 27 | 50 | 3.5 | 8 | |||

| M45.HN07.B32.100.Z10 | 100 | 32 | 63 | 3.5 | 10 | |||

| M45.HN07.B40.125.Z12 | 125 | 40 | 63 | 3.5 | 12 | |||

| M45.HN07.B40.160.Z16 | 160 | 40 | 63 | 3.5 | 16 | |||

| M45.HN07.B40.200.Z20 | 200 | 40 | 63 | 3.5 | 20 | |||

| M45.HN07.B22.050.Z05-L | 50 | 22 | 40 | 3.5 | 5 | |||

| M45.HN07.B22.063.Z06-L | 63 | 22 | 40 | 3.5 | 6 | |||

| M45.HN07.B27.080.Z08-L | 80 | 27 | 50 | 3.5 | 8 | |||

| M45.HN07.B32.100.Z10-L | 100 | 32 | 63 | 3.5 | 10 | |||

| M45.HN07.B40.125.Z12-L | 125 | 40 | 63 | 3.5 | 12 | |||

| M45.HN07.B40.160.Z16-L | 160 | 40 | 63 | 3.5 | 16 | |||

| M45.HN07.B40.200.Z20-L | 200 | 40 | 63 | 3.5 | 20 |

|

Insert Type |

D mm |

S mm |

R mm |

| HN..0704.. | 12.7 | 4.48 | 1.2 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| HNPJ0704ANSNGD TN5515 | - | - | FCK20 | - |

| HNGJ0704ANFNLDJ TN6501 | - | - | - | FCN20 |

| HNPJ0704ANSNHD TN7535 | FCP20 | - | - | - |

| XNGJ0704ANENLD3W | - | - | FCK20 | FCK20 |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 50-200 | 0.25 | 0.20 | 0.20 | 0.15 | 0.12 | 0.30 | 0.25 | 0.25 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||