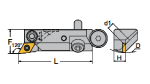

| Type | a mm | D mm | d1 mm | F mm | H mm | L mm | Insert Type | Screw | Holder Radial Adjust Screw | Holder Axial Adjust Screw | Lock Screw | Key | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FCR653 | - | 40 | 6 | 18.3 | 10 | 30.3 | CC..09T3.. | FCS359 | FCS384 | FCS384 | FCS965 | TORX15 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL653 | - | 40 | 6 | 18.3 | 10 | 30.3 | CC..09T3.. | FCS359 | FCS384 | FCS384 | FCS965 | TORX15 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR655 | - | 48 | 7 | 22.3 | 12 | 36.3 | CC..1204.. | FCS1030 | FCS384 | FCS384 | FCS964 | TORX20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL655 | - | 48 | 7 | 22.3 | 12 | 36.3 | CC..1204.. | FCS1030 | FCS384 | FCS384 | FCS964 | TOEX20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FCR658 | - | 40 | 6 | 18.3 | 10 | 30.3 | CC..09T3.. | FCS359 | FCS384 | FCS384 | FCS965 | TORX15 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL658 | - | 40 | 6 | 18.3 | 10 | 30.3 | CC..09T3.. | FCS359 | FCS384 | FCS384 | FCS965 | TORX15 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR659 | - | 48 | 7 | 22.3 | 12 | 36.3 | CC..1204.. | FCS1030 | FCS384 | FCS384 | FCS964 | TORX20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL659 | - | 48 | 7 | 22.3 | 12 | 36.3 | CC..1204.. | FCS1030 | FCS384 | FCS384 | FCS964 | TORX20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FCR654 | 2.0 | 40 | 6 | 18.3 | 10 | 28.3 | CC..09T3.. | FCS359 | FCS384 | FCS384 | FCS965 | TORX15 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL654 | 2.0 | 40 | 6 | 18.3 | 10 | 28.3 | CC..09T3.. | FCS359 | FCS384 | FCS384 | FCS965 | TORX15 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR656 | 2.8 | 48 | 7 | 22.3 | 12 | 33.5 | CC..1204.. | FCS1030 | FCS384 | FCS384 | FCS964 | TORX20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL656 | 2.8 | 48 | 7 | 22.3 | 12 | 33.5 | CC..1204.. | FCS1030 | FCS384 | FCS384 | FCS964 | TORX20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FCR646 | 6.1 | 40 | 6 | 18.3 | 10 | 28.3 | CC..09T3.. | FCS359 | FCS384 | FCS384 | FCS965 | TORX15 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL646 | 6.1 | 40 | 6 | 18.3 | 10 | 28.3 | CC..09T3.. | FCS359 | FCS384 | FCS384 | FCS965 | TORX15 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR650 | 8.3 | 48 | 7 | 22.3 | 12 | 33.5 | CC..1204.. | FCS1030 | FCS384 | FCS384 | FCS964 | TORX20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL650 | 8.3 | 48 | 7 | 22.3 | 12 | 33.5 | CC..1204.. | FCS1030 | FCS384 | FCS384 | FCS964 | TORX20 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FCR670 | - | 14.5 | 3.4 | 8 | 6 | 25 | CP..0502.. | FCS1020 | FCS493 | FCS1023 | FCS1024 | TORX07 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL670 | - | 14.5 | 3.4 | 8 | 6 | 25 | CP..0502.. | FCS1020 | FCS493 | FCS1023 | FCS1024 | TORX07 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR671 | - | 20 | 3.4 | 9.7 | 6 | 25 | CC..0602.. | FCS924 | FCS493 | FCS1023 | FCS1024 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL671 | - | 20 | 3.4 | 9.7 | 6 | 25 | CC..0602.. | FCS924 | FCS493 | FCS1023 | FCS1024 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR672 | - | 20 | 4.5 | 11 | 8 | 28 | TC..1102.. | FCS924 | FCS493 | FCS1023 | FCS1025 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL672 | - | 20 | 4.5 | 11 | 8 | 28 | TC..1102.. | FCS924 | FCS493 | FCS1023 | FCS1025 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR673 | 7.4 | 20 | 4.5 | 10.8 | 8 | 22.8 | TC..1102.. | FCS924 | FCS493 | FCS1023 | FCS1025 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL673 | 7.4 | 20 | 4.5 | 10.8 | 8 | 22.8 | TC..1102.. | FCS924 | FCS493 | FCS1023 | FCS1025 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR674 | 9.1 | 20 | 1.5 | 11 | 8 | 18.9 | TC..1102.. | FCS924 | FCS493 | FCS1023 | FCS1025 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL674 | 9.1 | 20 | 1.5 | 11 | 8 | 18.9 | TC..1102.. | FCS924 | FCS493 | FCS1023 | FCS1025 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR675 | 5.2 | 20 | 4.5 | 10.8 | 8 | 22.8 | TC..1102.. | FCS924 | FCS493 | FCS1023 | FCS1025 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCL675 | 5.2 | 20 | 4.5 | 10.8 | 8 | 22.8 | TC..1102.. | FCS924 | FCS493 | FCS1023 | FCS1025 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR679 | - | 14.5 | 3.4 | 8 | 6 | 25 | WC..0302.. | FCS1020 | FCS493 | FCS1023 | FCS1024 | TORX07 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FCR680 | - | 20 | 3.4 | 9.7 | 6 | 25 | WC..0402.. | FCS924 | FCS493 | FCS1023 | FCS1024 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SCFCL09CA06-FB | - | 28 | 4.5 | 15.9 | 8.5 | 45.5 | CC..0602.. | FCS924 | - | - | FCS1354 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SCFCR09CA06-FB | - | 28 | 4.5 | 15.9 | 8.5 | 45.5 | CC..0602.. | FCS924 | - | - | FCS1354 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SCLCL09CA06-FB | - | 28 | 4.5 | 15.9 | 8.5 | 45.5 | CC..0602.. | FCS924 | - | - | FCS1354 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SCLCR09CA06-FB | - | 28 | 4.5 | 15.9 | 8.5 | 45.5 | CC..0602.. | FCS924 | - | - | FCS1354 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SDLCL09CA07-FB | - | 28 | 4.5 | 15.9 | 8.5 | 48.6 | DC..0702.. | FCS924 | - | - | FCS1354 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SDLCR09CA07-FB | - | 28 | 4.5 | 15.9 | 8.5 | 48.6 | DC..0702.. | FCS924 | - | - | FCS1354 | TORX08 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type | shallow hole drill -3xDc-WC | shallow hole drill -3xDc-WC | Solid carbide drilling tool-3xDc with 45° chamfer | ||||||||||||

| Diameter | Vc | 20-30 | >30 | Vc | 15.8- 20.4 | 20.5- 30.4 | >30.4 | 15.8- 20.4 | 20.5- 30.4 | >30.4 | Vc | 5-7 | 7.1-11 | 11.1-16 | |

| Insert Categor | P28467/P28477 | P28469/P29479/P28475 | |||||||||||||

| P | Unalloyed steel | 200 | 0.08 | 0.10 |

200 |

0.07 | 0.08 | 0.10 | 0.08 | 0.10 | 0.14 | - | - | - | - |

| Low alloyed steel | 190 | 0.08 | 0.10 | 190 | 0.07 | 0.08 | 0.10 | 0.07 | 0.10 | 0.12 | - | - | - | - | |

| Tool steel | 140 | 0.07 | 0.10 | 140 | 0.05 | 0.07 | 0.10 | 0.08 | 0.10 | 0.14 | - | - | - | - | |

| Martensitic stainless steel |

140 |

0.08 | 0.10 | 140 | 0.06 | 0.08 | 0.10 | 0.07 | 0.09 | 0.10 | - | - | - | - | |

| M | Austenitic stainless steel | 180 | 0.08 | 0.10 | 180 | 0.06 | 0.08 | 0.10 | 0.07 | 0.09 | 0.10 | - | - | - | - |

| K | Grey cast iron | 180 | 0.10 | 0.16 | 180 | 0.08 | 0.10 | 0.16 | 0.08 | 0.10 | 0.16 | 100 | 0.16 | 0.22 | 0.27 |

| Ductile cast iron | 140 | 0.10 | 0.16 | 140 | 0.08 | 0.10 | 0.16 | 0.08 | 0.10 | 0.16 | 85 | 0.16 | 0.22 | 0.27 | |

| Malleable iron | 180 | 0.10 | 0.16 | 180 | 0.08 | 0.10 | 0.16 | 0.08 | 0.10 | 0.16 | 85 | 0.16 | 0.22 | 0.27 | |

| N | Aluminium alloy | 300 | 0.10 | 0.14 | 300 |

- |

- | - | 0.08 | 0.10 | 0.14 |

200 |

0.22 | 0.27 | 0.34 |

| Copper alloy | 300 | 0.10 | 0.14 | 300 |

- |

- | - | 0.08 | 0.10 | 0.14 | 105 | 0.22 | 0.27 |

0.34 |

|

| Non-metallic materials | 300 | 0.10 | 0.14 | 300 |

- |

- | - | 0.08 | 0.10 | 0.14 |

100 |

0.25 | 0.28 | 0.32 | |

| Type | Reaming Boring Cutter | ||||

| Diameter | Vc | <44 | 44-73 | >73 | |

| Insert Category | |||||

| P | Unalloyed steel | 200 | 0.13 | 0.19 | 0.32 |

| Low alloyed steel | 190 | 0.13 | 0.19 | 0.32 | |

| Tool steel | 140 | 0.11 | 0.16 | 0.24 | |

| Martensitic stainless steel | 140 | 0.10 | 0.13 | 0.19 | |

| M | Austenitic stainless steel | 180 | 0.10 | 0.13 | 0.19 |

| K | Grey cast iron | 180 | 0.13 | 0.19 | 0.24 |

| Ductile cast iron | 140 | 0.13 | 0.19 | 0.24 | |

| Malleable iron | 180 | 0.13 | 0.19 | 0.24 | |

| N | Aluminium alloy | 300 | 0.24 | 0.30 | 0.40 |

| Copper alloy | 300 | 0.24 | 0.30 | 0.40 | |

| Non-metallic materials | 300 | 0.24 | 0.30 | 0.40 | |