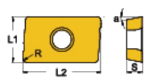

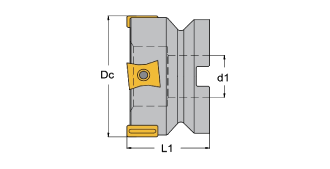

| 90°铣刀-AP09 | 90°milling cutter-AP09 | |

|

|

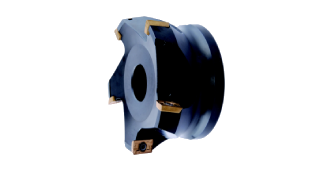

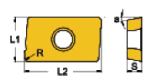

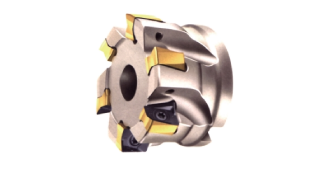

FIG1 |

|

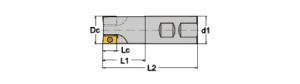

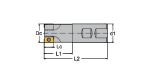

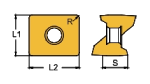

FIG2 | |

| Type |

Dc mm |

d1 mm |

L1 mm |

L2 mm |

Lcmm | Z | Insert Type | Screw | Key |

Drawing No. |

| M90.AP09.W16.010.Z01 | 10 | 16 | 31 | 80 | 9 | 1 | AP..0903.. | FCS923 | TORX08 | FIG1 |

| M90.AP09.W16.012.Z01 | 12 | 16 | 31 | 80 | 9 | 1 | ||||

| M90.AP09.W16.016.Z02 | 16 | 16 | 41 | 90 | 9 | 2 | ||||

| M90.AP09.W20.020.Z03 | 20 | 20 | 39 | 90 | 9 | 3 | ||||

| M90.AP09.W20.025.Z04 | 25 | 20 | 39 | 90 | 9 | 4 | ||||

| M90.AP09.W20.032.Z05 | 32 | 20 | 39 | 90 | 9 | 5 | ||||

| M90.AP09.W25.025.Z04 | 25 | 25 | 43 | 100 | 9 | 4 | ||||

| M90.AP09.W32.032.Z05 | 32 | 32 | 49 | 110 | 9 | 5 | ||||

| M90.AP09.W32.040.Z06 | 40 | 32 | 49 | 110 | 9 | 6 | ||||

| M90.AP09.Z16.010.Z01 | 10 | 16 | 31 | 160 | 9 | 1 | ||||

| M90.AP09.Z16.012.Z01 | 12 | 16 | 31 | 160 | 9 | 1 | ||||

| M90.AP09.Z16.016.Z02 | 16 | 16 | 41 | 180 | 9 | 2 | ||||

| M90.AP09.Z20.020.Z02 | 20 | 20 | 39 | 200 | 9 | 2 | ||||

| M90.AP09.Z25.025.Z03 | 25 | 25 | 43 | 200 | 9 | 3 | ||||

| M90.AP09.Z32.032.Z04 | 32 | 32 | 49 | 250 | 9 | 4 | ||||

| M90.AP09.Z32.040.Z05 | 40 | 32 | 49 | 250 | 9 | 5 | ||||

| M90.AP09.B16.040.Z04 | 40 | 16 | 40 | / | 9 | 4 | FIG2 | |||

| M90.AP09.B16.040.Z06 | 40 | 16 | 40 | / | 9 | 6 | ||||

| M90.AP09.B22.050.Z05 | 50 | 22 | 40 | / | 9 | 5 | ||||

| M90.AP09.B22.050.Z07 | 50 | 22 | 40 | / | 9 | 7 | ||||

| M90.AP09.B22.063.Z06 | 63 | 22 | 40 | / | 9 | 6 | ||||

| M90.AP09.B22.063.Z08 | 63 | 22 | 40 | / | 9 | 8 |

|

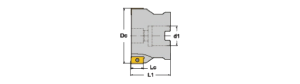

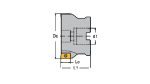

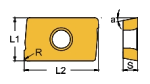

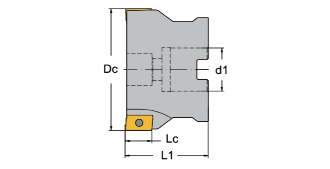

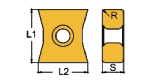

Insert Type |

L1 mm |

L2 mm |

a° |

S mm |

R mm |

| AP..0903.. | 6.75 | 9.52 | 11 | 3.18 | 0.4 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| APMT0903PPR-F56 | FPK20 | FCM20 | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 16-63 | 0.15 | 0.10 | 0.10 | 0.08 | 0.08 | 0.15 | 0.12 | 0.12 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 90°铣刀- AP11 | 90° milling cutter -AP11 |

| Type |

Dc mm |

d1 mm |

L1 mm |

L2 mm |

Lcmm | Z | Insert Type | Screw | Key |

Drawing No. |

| M90.AP11.W16.010.Z01 | 10 | 16 | 31 | 80 | 9 | 1 | AP..1135. | FCS923 | TORX08 | FIG1 |

| M90.AP11.W16.012.Z01 | 12 | 16 | 31 | 80 | 9 | 1 | ||||

| M90.AP11.W16.016.Z02 | 16 | 16 | 41 | 90 | 9 | 2 | ||||

| M90.AP11.W20.020.Z03 | 20 | 20 | 39 | 90 | 9 | 3 | ||||

| M90.AP11.W20.025.Z04 | 25 | 20 | 39 | 90 | 9 | 4 | ||||

| M90.AP11.W20.032.Z05 | 32 | 20 | 39 | 90 | 9 | 5 | ||||

| M90.AP11.W25.025.Z04 | 25 | 25 | 43 | 100 | 9 | 4 | ||||

| M90.AP11.W32.032.Z05 | 32 | 32 | 49 | 110 | 9 | 5 | ||||

| M90.AP11.W32.040.Z06 | 40 | 32 | 49 | 110 | 9 | 6 | ||||

| M90.AP11.Z20.020.Z02 | 20 | 20 | 39 | 200 | 9 | 2 | ||||

| M90.AP11.Z25.025.Z03 | 25 | 25 | 43 | 200 | 9 | 3 | ||||

| M90.AP11.Z32.032.Z04 | 32 | 32 | 49 | 250 | 9 | 4 | ||||

| M90.AP11.Z32.040.Z05 | 40 | 32 | 49 | 250 | 9 | 5 |

|

Insert Type |

L1 mm |

L2 mm |

a° |

S mm |

R mm |

| AP..1135.. | 6.2 | 11.21 | 11 | 3.5 | 0.8 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| APMT1135PDER-M2 | FPK20 | - | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 16-40 | 0.15 | 0.10 | 0.10 | 0.08 | - | 0.15 | 0.12 | 0.12 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 90°铣刀- AP15 | 90° milling cutter -AP15 |

| Type |

Dc mm |

d1 mm |

L1 mm |

L2 mm |

Lcmm | Z | Insert Type | Screw | Key |

Drawing No. |

| M90.AP15.W20.020.Z01 | 20 | 20 | 43 | 90 | 15 | 1 | AP..15T3. | FCS359 | TORX15 | FIG1 |

| M90.AP15.W25.025.Z02 | 25 | 25 | 49 | 100 | 15 | 2 | ||||

| M90.AP15.W32.032.Z03 | 32 | 32 | 49 | 110 | 15 | 3 | ||||

| M90.AP15.W32.040.Z04 | 40 | 32 | 38 | 110 | 15 | 4 | ||||

| M90.AP15.Z25.025.Z02 | 25 | 25 | 39 | 200 | 15 | 2 | ||||

| M90.AP15.Z32.032.Z03 | 32 | 32 | 44 | 250 | 15 | 3 | ||||

| M90.AP15.Z40.040.Z03 | 40 | 40 | 40 | 250 | 15 | 3 | ||||

| M90.AP15.B16.040.Z04 | 40 | 16 | 40 | / | 15 | 4 | FIG2 | |||

| M90.AP15.B22.050.Z05 | 50 | 22 | 40 | / | 15 | 5 | ||||

| M90.AP15.B22.063.Z04 | 63 | 22 | 40 | / | 15 | 4 | ||||

| M90.AP15.B22.063.Z06 | 63 | 22 | 50 | / | 15 | 6 | ||||

| M90.AP15.B27.080.Z05 | 80 | 27 | 50 | / | 15 | 5 | ||||

| M90.AP15.B27.080.Z07 | 80 | 27 | 50 | / | 15 | 7 | ||||

| M90.AP15.B32.100.Z05 | 100 | 32 | 50 | / | 15 | 5 | ||||

| M90.AP15.B32.100.Z08 | 100 | 32 | 50 | / | 15 | 8 | ||||

| M90.AP15.B40.125.Z06 | 125 | 40 | 63 | / | 15 | 6 | ||||

| M90.AP15.B40.125.Z10 | 125 | 40 | 63 | / | 15 | 10 | ||||

| M90.AP15.B40.160.Z07 | 160 | 40 | 63 | / | 15 | 7 | ||||

| M90.AP15.B40.160.Z12 | 160 | 40 | 63 | / | 15 | 12 |

|

Insert Type |

L1 mm |

L2 mm |

a° |

R mm |

| AP.15T3.. | 9.52 | 15.88 | 11 | 3.97 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| APMT15T3PDR-F56 | FPK20 | FCM20 | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 20-160 | 0.20 | 0.15 | 0.15 | 0.12 | 0.10 | 0.25 | 0.20 | 0.20 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 90°铣刀- AP16 | 90° milling cutter -AP16 |

| Type |

Dc mm |

d1 mm |

L1 mm |

L2 mm |

Lcmm | Z | Insert Type | Screw | Key |

Drawing No. |

| M90.AP16.W25.025.Z02 | 25 | 25 | 43 | 100 | 15 | 2 | AP..1604.. | FCS378 | TORX15 | FIG1 |

| M90.AP16.W32.032.Z03 | 32 | 32 |

49 |

110 | 15 | 3 | ||||

| M90.AP16.W32.040.Z04 | 40 | 32 | 49 | 110 | 15 | 4 | ||||

| M90.AP16.Z25.025.Z02 | 25 | 25 | 38 | 200 | 15 | 2 | ||||

| M90.AP16.Z32.032.Z03 | 32 | 32 | 39 | 250 | 15 | 3 | ||||

| M90.AP16.740.040.703 | 40 | 40 | 44 | 250 | 15 | 4 | ||||

| M90.AP16.B16.040.Z04 | 40 | 16 | 40 | / | 15 | 4 | FIG2 | |||

| M90.AP16.B22.050.Z05 | 50 | 22 | 40 | / | 15 | 5 | ||||

| M90.AP16.B22.063.Z06 | 63 | 22 | 40 | / | 15 | 6 | ||||

| M90.AP16.B27.080.Z07 | 80 | 27 | 50 | / | 15 | 7 | ||||

| M90.AP16.B32.100.Z08 | 100 | 32 | 50 | / | 15 | 8 | ||||

| M90.AP16.B40.125.Z10 | 125 | 40 | 63 | / | 15 | 10 | ||||

| M90.AP16.B40.160.Z12 | 160 | 40 | 63 | / | 15 | 12 |

|

Insert Type |

L1 mm |

L2 mm |

a° |

S mm |

R mm |

| AP..1604.. | 16.5 | 9.525 | 11 | 4.76 | 0.8 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| APMT1604PDER-H2 | FCP20 | - | FCK20 | - |

| APGT160408 | - | - | - | PCD20 |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 25-160 | 0.20 | 0.15 | 0.15 | 0.12 | - | 0.25 | 0.20 | 0.20 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 90°铣刀- AP12 | 90° milling cutter -AP12 |

| Type |

Dc mm |

d1 mm |

L1 mm |

L2 mm |

Lcmm | Z | Insert Type | Screw | Key |

Drawing No. |

| M90.AD12.W20.020.Z02-STE | 20 | 20 | 32 | 82 | 12 | 2 | ADGT12T3PD.. | FCS9015 | TORX10 | FIG1 |

| M90.AD12.W25.025.Z02-STE | 25 | 25 | 40 | 96 | 12 | 2 | ||||

| M90.AD12.W32.032.Z03-STE | 32 | 32 | 40 | 100 | 12 | 3 | ||||

| M90.AD12.B22.050.Z05-STE | 50 | 22 | 40 | / | 12 | 5 | FIG2 | |||

| M90.AD12.B22.063.Z06-STE | 63 | 22 | 40 | / | 12 | 6 | ||||

| M90.AD12.B27.080.Z07-STE | 80 | 27 | 50 | / | 12 | 7 |

|

Insert Type |

L1 mm |

L2 mm |

a° |

S mm |

R mm |

| ADGT12T3PD.. | 8 | 12.9 | 15 | 3.97 | 0.8 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| ADHT12T3PDER-46 | FPK20 | - | FPK20 | - |

| ADHT12T3PDER-46 | - | FCM20 | - | - |

| ADGT12T3PDFR-721 | - | - | - | FCN20 |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 20-80 | 0.20 | 0.15 | 0.15 | 0.12 | 0.10 | 0.25 | 0.20 | 0.20 | 0.15 | 0.12 | 0.12 |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 90°铣刀- AP15 | 90° milling cutter -AP15 |

| Type |

Dc mm |

d1 mm |

L1 mm |

L2 mm |

Lcmm | Z | Insert Type | Screw | Key |

Drawing No. |

| M90.AD15.W25.025.Z02 | 25 | 25 | 43 | 100 | 15 | 2 | AD..1505.. | FCS378 | TORX15 | FIG1 |

| M90.AD15.W32.032.Z03 | 32 | 32 | 49 | 110 | 15 | 3 | ||||

| M90.AD15.W32.040.Z04 | 40 | 32 | 49 | 110 | 15 | 4 | ||||

| M90.AD15.Z25.025.Z02 | 25 | 25 | 38 | 200 | 15 | 2 | ||||

| M90.AD15.Z32.032.Z03 | 32 | 32 | 39 | 250 | 15 | 3 | ||||

| M90.AD15.Z40.040.Z03 | 40 | 40 | 44 | 250 | 15 | 3 | ||||

| M90.AD15.B16.040.Z04 | 40 | 16 | 40 | / | 15 | 4 | FIG2 | |||

| M90.AD15.B22.050.Z05 | 50 | 22 | 40 | / | 15 | 5 | ||||

| M90.AD15.B22.063.Z06 | 63 | 22 | 40 | / | 15 | 6 | ||||

| M90.AD15.B27.080.Z07 | 80 | 27 | 50 | / | 15 | 7 | ||||

| M90.AD15.B32.100.Z08 | 100 | 32 | 50 | / | 15 | 8 | ||||

| M90.AD15.B40.125.Z10 | 125 | 40 | 63 | / | 15 | 10 | ||||

| M90.AD15.B40.160.Z12 | 160 | 40 | 63 | / | 15 | 12 |

|

Insert Type |

L1 mm |

L2 mm |

a° |

S mm |

R mm |

| AD..1505.. | 9.6 | 15.95 | 15 | 5.64 | 0.8-6.4 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| ADCT1505PDSR | FPK20 | FCM20 | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 25-160 | 0.20 | 0.15 | 0.15 | 0.12 | 0.10 | 0.25 | 0.20 | 0.20 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 低切削力90°铣刀 | 90°milling cutter with low cutting force | |

|

|

FIG1 |

|

FIG2 | |

| Type |

Dc mm |

d1 mm |

L1 mm |

L2 mm |

Lcmm | Z | Insert Type | Screw | Key |

Drawing No. |

| M90.AD08.W16.010.Z01 | 10 | 16 | 31 | 80 | 8 | 1 | AD..0803.. | FCS1455 | TORX08 IP | FIG1 |

| M90.AD08.W16.012.Z01 | 12 | 16 | 31 | 80 | 8 | 1 | ||||

| M90.AD08.W16.016.Z02 | 16 | 16 | 41 | 90 | 8 | 2 | ||||

| M90.AD08.W20.020.Z03 | 20 | 20 | 39 | 90 | 8 | 3 | ||||

| M90.AD08.W25.025.Z04 | 25 | 25 | 43 | 100 | 8 | 4 | FCS1454 | |||

| M90.AD08.W32.032.Z05 | 32 | 32 | 49 | 110 | 8 | 5 | ||||

| M90.AD08.W32.040.Z06 | 40 | 32 | 49 | 110 | 8 | 6 | ||||

| M90.AD08.Z16.010.Z01 | 10 | 16 | 31 | 160 | 8 | 1 | FCS1455 | |||

| M90.AD08.Z16.012.Z01 | 12 | 16 | 31 | 160 | 8 | 1 | ||||

| M90.AD08.Z16.016.Z02 | 16 | 16 | 41 | 180 | 8 | 2 | ||||

| M90.AD08.Z20.020.Z02 | 20 | 20 | 39 | 200 | 8 | 2 | ||||

| M90.AD08.Z25.025.Z03 | 25 | 25 | 43 | 200 | 8 | 3 | FCS1454 | |||

| M90.AD08.B16.040.Z06 | 40 | 16 | 40 | / | 8 | 6 | FIG2 | |||

| M90.AD08.B22.050.Z07 | 50 | 22 | 40 | / | 8 | 7 | ||||

| M90.AD12.W25.025.Z03 | 25 | 25 | 43 | 100 | 12 | 3 | AD..1204.. | FCS1456 | TORX9 IP | FIG1 |

| M90.AD12.W32.032.Z04 | 32 | 32 | 49 | 110 | 12 | 4 | FCS1457 | |||

| M90.AD12.W32.040.Z05 | 40 | 32 | 49 | 110 | 12 | 5 | ||||

| M90.AD12.Z25.025.Z03 | 25 | 25 | 38 | 200 | 12 | 3 | FCS1456 | |||

| M90.AD12.Z32.032.Z04 | 32 | 32 | 39 | 250 | 12 | 4 | FCS1457 | |||

| M90.AD12.Z32.040.Z05 | 40 | 32 | 44 | 250 | 12 | 5 | ||||

| M90.AD12.B16.040.Z05 | 40 | 16 | 40 | / | 12 | 5 | FIG2 | |||

| M90.AD12.B22.050.Z06 | 50 | 22 | 40 | / | 12 | 6 | ||||

| M90.AD12.B22.063.Z07 | 63 | 22 | 50 | / | 12 | 7 | ||||

| M90.AD12.B27.080.Z08 | 80 | 27 | 50 | / | 12 | 8 | ||||

| M90.AD16.B16.040.Z04 | 40 | 16 | 40 | / | 15 | 4 | AD..1606.. | FCS1453 | TORX15IP | FIG2 |

| M90.AD16.B22.050.Z05 | 50 | 22 | 40 | / | 15 | 5 | ||||

| M90.AD16.B22.063.Z04 | 63 | 22 | 40 | / | 15 | 4 | ||||

| M90.AD16.B22.063.Z06 | 63 | 22 | 40 | / | 15 | 6 | ||||

| M90.AD16.B27.080.Z05 | 80 | 27 | 50 | / | 15 | 5 | ||||

| M90.AD16.B27.080.Z07 | 80 | 27 | 50 | / | 15 | 7 | ||||

| 490.AD16.B32.100.Z05 | 100 | 32 | 50 | / | 15 | 5 | ||||

| 490.AD16.B32.100.Z08 | 100 | 32 | 50 | / | 15 | 8 | ||||

| M90.AD16.B40.125.Z07 | 125 | 40 | 63 | / | 15 | 7 | ||||

| M90.AD16.B40.125.Z10 | 125 | 40 | 63 | / | 15 | 10 | ||||

| M90.AD16.B40.160.Z08 | 160 | 40 | 63 | / | 15 | 8 | ||||

| M90.AD16.B40.160.Z12 | 160 | 40 | 63 | / | 15 | 12 |

|

Insert Type |

L1 mm |

L2 mm |

a° |

S mm |

| AD..0803.. | 6.26 | 8 | 15/20 | 3.35 | |

| AD..1204.. | 7.64 | 12 | 15/20 | 4.76 | |

| AD..1606.. | 9.85 | 16 | 15/20 | 6.15 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| ADMT080304R-F56 | FPK20 | FCM20 | FPK20 | - |

| ADMT120408R-F56 | FPK20 | FCM20 | FPK20 | - |

| ADMT160608R-F56 | FPK20 | FCM20 | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 10-50(AD08) | 0.15 | 0.10 | 0.10 | 0.08 | 0.08 | 0.15 | 0.12 | 0.12 | - | - | - |

| 25-80(AD12) | 0.20 | 0.15 | 0.15 | 0.12 | 0.10 | 0.25 | 0.20 | 0.20 | - | - | - |

| 40-160(AD16) | 0.25 | 0.18 | 0.18 | 0.15 | 0.12 | 0.30 | 0.25 | 0.25 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 低切削力90°铣刀-负型 | 90°milling cutter with low cutting force - negative type |

|

|

| Type |

Dc mm |

d1 mm |

L1 mm |

Lcmm | Z | Insert Type | Screw | Key |

| M90.LN13.B16.040.Z03 | 40 | 16 | 40 | 13 | 3 | LN..1307.. | FS1458 | TORX15IP |

| M90.LN13.B22.050.Z04 | 50 | 22 | 40 | 13 | 4 | |||

| M90.LN13.B22.063.Z04 | 63 | 22 | 40 | 13 | 4 | |||

| M90.LN13.B22.063.Z06 | 63 | 22 | 40 | 13 | 6 | |||

| M90.LN13.B27.080.Z05 | 80 | 27 | 50 | 13 | 5 | |||

| M90.LN13.B27.080.Z07 | 80 | 27 | 50 | 13 | 7 | |||

| M90.LN13.B32.100.Z05 | 100 | 32 | 50 | 13 | 5 | |||

| M90.LN13.B32.100.Z08 | 100 | 32 | 50 | 13 | 8 | |||

| M90.LN13.B40.125.Z07 | 125 | 40 | 63 | 13 | 7 | |||

| M90.LN13.B40.125.Z10 | 125 | 40 | 63 | 13 | 10 | |||

| M90.LN13.B40.160.Z08 | 160 | 40 | 63 | 13 | 8 | |||

| M90.LN13.B40.160.Z12 | 160 | 40 | 63 | 13 | 12 |

|

Insert Type |

L1 mm |

L2 mm |

S mm |

R mm |

| LN..1307.. | 11 | 13.6 | 7.94 | 0.8 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| LNGX130708R-L55 | FPK20 | FCM20 | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 40-160 | 0.20 | 0.15 | 0.15 | 0.12 | 0.10 | 0.25 | 0.20 | 0.20 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||

| 低切削力90°铣刀-负型 | 90°milling cutter with low cutting force - negative type |

|

|

| Type |

Dc mm |

d1 mm |

L1 mm |

Lcmm | Z | Insert Type | Screw | Key |

| M90.LN11.B16.040.Z04-R/L | 40 | 16 | 40 | 5 | 4 | LN.1106.. | SR34-550 | TORX10 |

| M90.LN11.B22.050.Z05-R/L | 50 | 22 | 40 | 5 | 5 | |||

| M90.LN11.B22.063.Z06-R/L | 63 | 22 | 40 | 5 | 6 | |||

| M90.LN11.B27.080.Z08-R/L | 80 | 27 | 50 | 5 | 8 | |||

| M90.LN11.B32.100.Z09-R/L | 100 | 32 | 50 | 5 | 9 | |||

| M90.LN11.B40.125.Z10-R/L | 125 | 40 | 63 | 5 | 10 | |||

| M90.LN11.B40.160.Z12-R/L | 160 | 40 | 63 | 5 | 12 | |||

| M90.LN11.B60.200.Z16-R/L | 200 | 60 | 63 | 5 | 16 | |||

| M90.LN15.B22.050.Z05-R/L | 50 | 22 | 40 | 7 | 5 | LN..1506.. | FCS4010T | TORX15 |

| M90.LN15.B22.063.Z05-R/L | 63 | 22 | 40 | 7 | 5 | |||

| M90.LN15.B27.080.Z07-R/L | 80 | 27 | 50 | 7 | 7 | |||

| M90.LN15.B32.100.Z08-R/L | 100 | 32 | 50 | 7 | 8 | |||

| M90.LN15.B40.125.Z09-R/L | 125 | 40 | 63 | 7 | 9 | |||

| M90.LN15.B40.160.Z10-R/L | 160 | 40 | 63 | 7 | 10 | |||

| M90.LN15.B60.200.Z12-R/L | 200 | 60 | 63 | 7 | 12 | |||

| M90.LN15.B60.250.Z15-R/L | 250 | 60 | 63 | 7 | 25 |

|

Insert Type |

L1 mm |

L2 mm |

S mm |

R mm |

| LN..1106.. | 11.16 | 11 | 6 | 0.8 | |

| LN..1506.. | 15 | 14.4 | 6 | 0.8 |

| Material Type | P | M | K | N |

| Applicable lnsert Type |

Alloy steel |

Stainless steel |

Castiron |

Non-ferrous metals |

| LNKX1106PN-N MM | FPK20 | - | FPK20 | - |

| LNKX1106PN-N MM | FPK20 | - | FPK20 | - |

| Diameter Range(mm) | P | M | K | N | |||||||

|

Unalloyed steel |

Low alloyed steel |

Tool steel |

Martensitic stainless steel |

Austenitic stainless steel |

Grey cast iron |

Ductile cast iron |

Malleable iron |

Aluminium alloy |

Copper alloy |

Non-metallic materials |

|

| 40-250 | 0.25 | 0.20 | 0.15 | 0.12 | 0.07 | 0.25 | 0.15 | 0.15 | - | - | - |

| Starting value of feeds (per tooth mm): Suitable for common cutting conditions with a width of cut ≥ 1/2Dc; depth of cut≤ 1/2Lc | |||||||||||